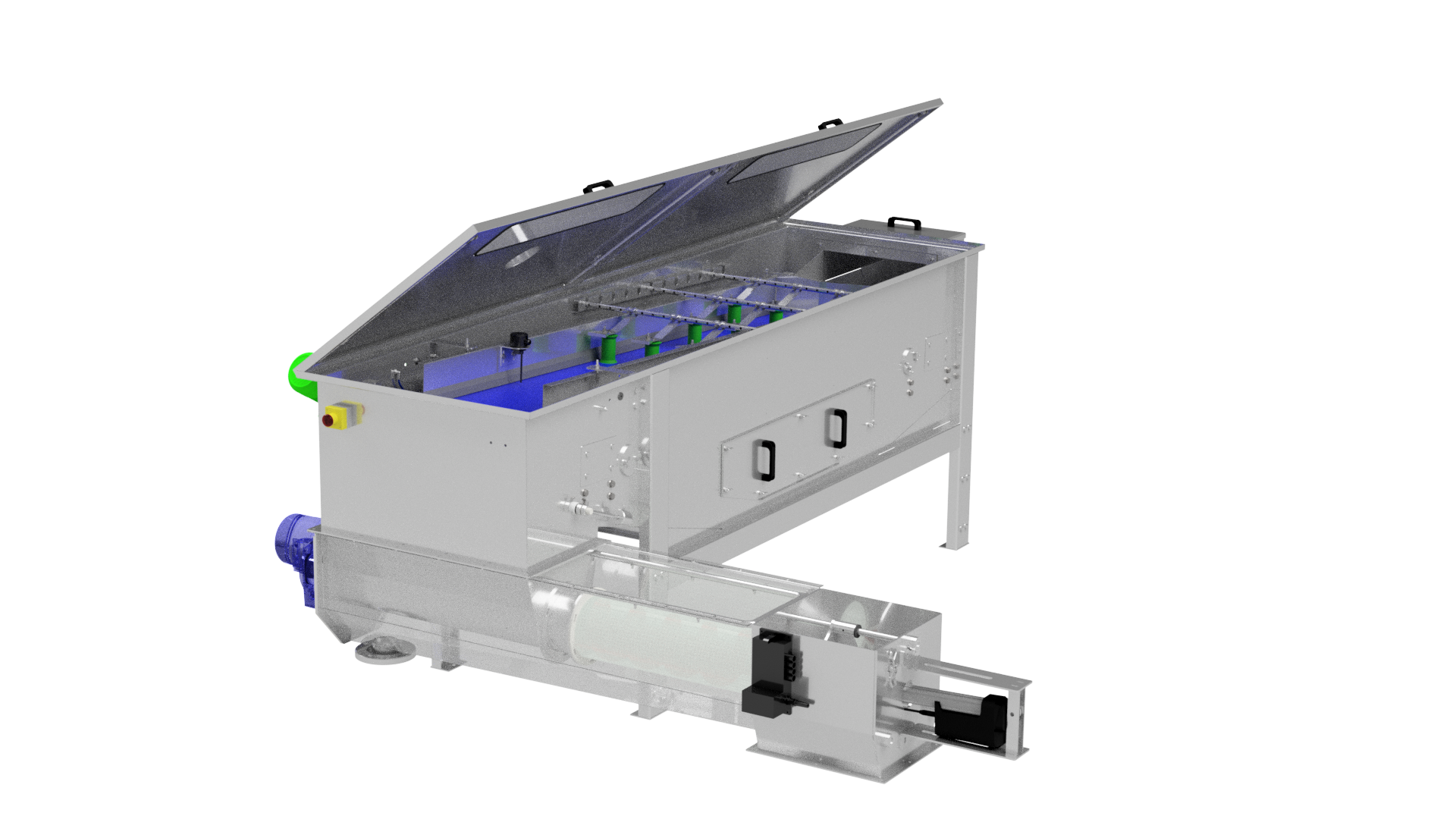

Our Screw Press (SP) is based on a shaft screw conveyor that transports the material to the press zone for higher dewatering. The material is dewatered in the long conveyor of the Screw Press. At the end, a counter pressure plug is formed of the already dewatered sludge, and by monitoring the counter pressure it can easily be adjusted. The DS-content is increased on the outlet sludge. The shafted screw makes it specifically suited for materials that tends to clog together. Shafted screw spirals reduce the need for maintenance, as they can operate with a significantly higher rate of filling in the conveyor without mechanical deformation. The screw press is optimal to be used behind our BT-thickener machine.

- Home

- Saltec Screw Press – SCP

SPECIFICATION

SPECIFICATION

| Model(BT/SSP) | BT Length (mm.) | SSP Length (mm.) | DS – Out (%) | Power (kW) | Capacity (m3/hr) |

| BT 5042/SSP | 4,200 | 2,800 | 15-25 | 0.37 | 0.5-1 |

| BT 9042/SSP | 4,200 | 2,800 | 15-25 | 0.37 | 1-5 |

| BT 17042/SSP | 4,200 | 3,800 | 15-25 | 0.55 | 3-8 |

| BT 22042/SSP | 4,200 | 4,300 | 15-25 | 0.55 | 5-10 |

*Approximate data in kg, and mm. Capacity at DS-in 4-13% DS-out 15-25%