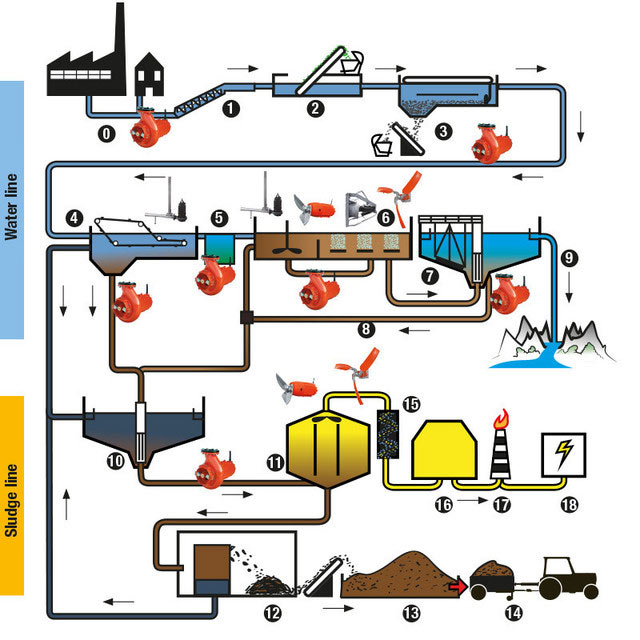

Waste water treatment process

Cri-Man machines can be used for the following applications in the WWTP.

PTS, ETO, and ETV Series Pumps

- Drain cleaning hatches. The drainage system can accumulate sediments of considerable bulk which are carried into drain cleaning hatches during rainy periods. The elimination of these is usually achieved using submersible chopper pumps that reduce them into more easily transported elements.

- Tanks for the wheeled removal of industrial effluents. The removal of industrial effluents is achieved using vacuum pumps that extract solid bodies of over 100 mm diameter. Extraction from the collection tank is conducted with chopper pumps.

- Hatches for removal of waste leachate.

- Full biological treatment, when the transport of the “effluent” is obstructed by the formation of fibrous materials that block the pipes and wind around mixer blades making them unbalanced.

In sections of the plant where effluent transport is required, including:

- Circulation of sludge sediments for denitrification.

- Evacuation of primary and secondary sludge from a decantation tank to a sludge thickener.

- Circulation in anaerobic digesters.

- Transfer to dehydration section.

ER Series Pumps

- Transfer of liquids between tanks with high capacity and very low pumping head (circulation from nitrification tank to denitrification tank).

TBM, AF, and TBX Series Mixers

- TBM: small tanks with coarse suspended solids (emptying hatches of various types), small balancing and denitrification tanks, anaerobic digesters (also ATEX version).

- AF: in “Carousel” tanks, sludge digesters.

- TBX: mixers for small tanks including “aggressive” effluents.

SMO and OXIGET Series Oxygenators

- Oxygenation tanks in small scale plants when it is a priority to avoid plant management problems.